In aerodynamics, there are various categories of drag used to provide a distinctive classification of different types. Due to the depth and complexity often surrounding the aerodynamics of an airfoil, it is necessary to clarify the enforcing drag types present.

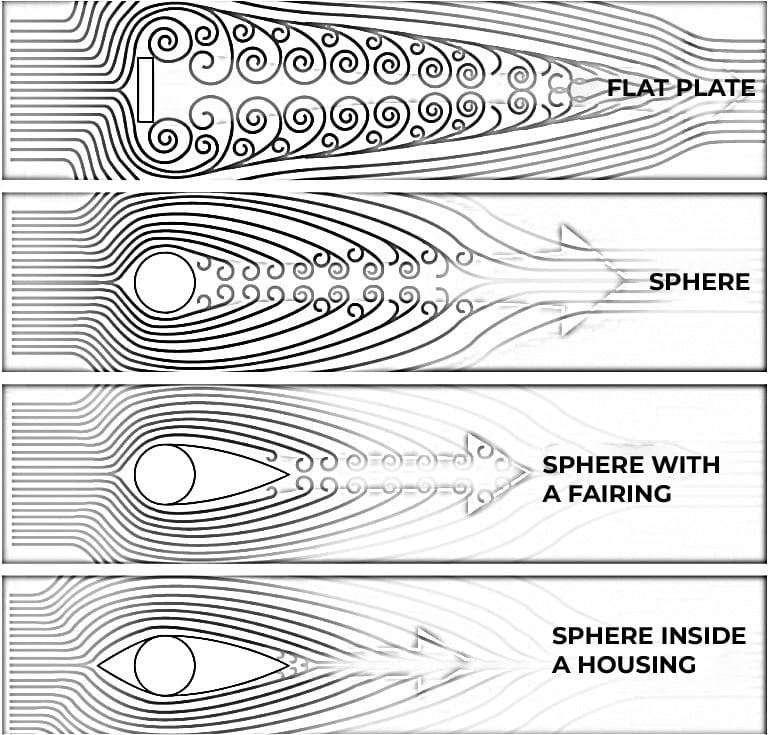

Form drag can be defined as the drag created following the departure of airflow (known as the boundary layer) across a surface. The subsequent effects are known as form drag.

The exact amount of form drag created is dependent on the outline of the surface from which it has separated from along with the surface area in which it involves.

Form drag is the product of parasitic drag in which airflow separates from an airfoil or body (a component of the aircraft).

As a result of this, airfoils and sections in which form drag is prone to occur are designed to be as optimal and streamlined as possible.

Form drag may also be referred to as profile drag or pressure drag.

How is Form Drag Produced?

Form drag is produced due to the differential pressure which exists between the pressure flow of an object through the air along with the shape and surfaces of that object. The slimmer and well-rounded shapes create less form drag than that of thicker and uneven surfaces.

The degree of form drag incurred will also depend on the relative wind and speed present across the body passing through the air.

As a result of this outcome, airfoils are designed to be as aerodynamically thin and round-edged where possible. However, it is impossible to eliminate form drag completely due to the subtle or gradual differences in shape and surface area across an airfoil or component.

This is also due to the different levels of pressure experienced across an airfoil or body passing through the air. Various points recorded across a surface will yield different levels and intensities of pressure.

It is essential however that aircraft designers minimize the potential for form drag to occur by creating aerodynamically efficient designs.

Reducing form drag is integral to reducing fuel burn and the overall efficiency of an aircraft. Modern aerospace materials technology has evolved, with major airframe components such as wings and stabilizers now being manufactured from composite materials.

Composite materials provide a durable, lightweight design profile.

As well as the production of form drag, interference drag also occurs due to the combination of airflow streams generated across the body passing through the air and the relative wind direction and speed.

Factors Determining Form Drag

As detailed above, form drag is created across a body which passes through the air. While form drag will always be encountered to some degree, it is greatly minimized by streamlined, aerodynamic design of aircraft components and airfoils.

The factors determining the level of form drag generated include:

Aircraft Fuselage: Being the largest of the 5 main components of the airframe, the aircraft fuselage will naturally produce the most amount of form drag due to its surface area. Fuselage form drag can be reduced by a clean, streamlined design of the aircraft shape. This includes ensuring antennas installed externally on the fuselage are of an aerodynamic shape.

Wings and Horizontal Stabilizer: Both being airfoils, the wings and horizontal stabilizer of the aircraft should be of a suitable aerodynamic design fit for the purpose of the aircraft. For example, a straight wing design is beneficial for low speed, light aircraft while a swept wing is optimal for large commercial aircraft.

The specific role of an aircraft (civilian, military, GA etc) along with performance specifications associated with each will determine which wing is best suited for the intended purpose. In these designs, considerations in relation to drag are also taken into account.

Joint/Cross-Sections of the Fuselage: At the sections which join major airframe components such as the wings, fuselage, stabilizers, engines and landing gear, there is susceptibility for drag to be generated. A wing box, also known as a torque box is a primary structural component which provides structural integrity to the wings of fixed wing aircraft.

With this design, induced and form drag are minimized due to direct integration of the wings to the fuselage of the aircraft via the torque box.

However, there is always still some degree of form drag incurred.

Read More:

Cabin Altitude and Aircraft Altitude – Aircraft Pressurization

After visiting more than 60 countries, I have probably been on every type of plane there is and visited countless airports. I did my very first international solo trip to South Africa at the age of only 16 and haven’t really stopped traveling since.

Despite the adventurous travel itch, I do have a nerdy side as well – which is satisfied by writing about all things aviation “too boring” for my regular travel blog.